Gas Absorption Column Datasheet 3g681g

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report l4457

Overview 6h3y3j

& View Gas Absorption Column Datasheet as PDF for free.

More details h6z72

- Words: 976

- Pages: 4

DISCOVER

UOP Series: Heat & Mass Transfer Operations

WITH

GAS ABSORPTION COLUMN – UOP7

© Armfield Ltd. 2009

DEMONSTRATION CAPABILITIES >S tudy of the basic principles of the absorption of a gas into a liquid using a packed column >D emonstration of methods of gas and liquid quantitative analysis > Production of mass balances for a packed absorption column

The Armfield Gas Absorption Column has been designed to demonstrate the principles of gas absorption and to provide practical training in the operation of gas absorption plant.

>M ethod of transferring units, including calculation of NTU and HTU > Determination of the Mass Transfer Coefficient > Study of the hydrodynamic characteristics of a packed column > Determination of loading and flooding points

R

TY

OD

PR

AR 2 -Y R W

2 years

AN

ON AL L ARMFIE

LD

The latest version of this data sheet is available at:

www.armfield.co.uk/uop7

UCTS

<E X T E N D E D >

WARRANTY

issue 11

Description The packed absorption column is made up of two 80mm diameter clear acrylic sections ed end to end and installed vertically on a mild steel floor standing framework. The column is filled with 10mm x 10mm glass Raschig rings, which are representative of the type of packing used in gas absorption. Liquid for the process is stored in a 50.0 litre rectangular feed tank and a centrifugal pump is used to deliver the liquid to the top of the column where it falls through the packing and returns to the tank. A variable area flow meter in the recirculation line gives a direct reading of flow rate.

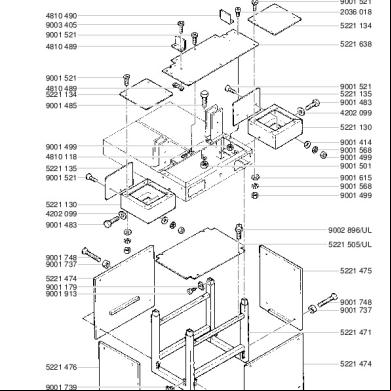

Pressure tappings at the base, centre and top of the column are provided to allow indication of pressure drop in the column using manometers. These tappings also provide a means of extracting samples of gas from the column. Carbon dioxide content of the gas samples is determined using a Hempl apparatus. Flow meters, manometers and gas analysis equipment are all mounted on a vertical backboard at a convenient height for operation.

2.5 litres/min

et

ng

i od

s on

Flo

O

Pressure drop

The gas to be absorbed is normally carbon dioxide and would be taken from a pressure cylinder (not supplied), standing adjacent to the column. This gas es through a calibrated variable area flow meter and is mixed with an air stream also of known flow rate from a rotary compressor positioned in the framework. The ratio of gas to air in the mixture entering the column is therefore known and is easily varied. Entering at the base of the column, the gas mixture rises up through the packed bed and is counter-currently ed with the liquid flowing down the column.

4 litres/min

Gas

TECHNICAL DETAILS Feed tank capacity: Internal diameter of column: Volume of packing: Height of absorption column:

50.0 litres 0.80mm 7.0 litres 1.4m

Type of packing: Air compressor capacity: Column feed pump capacity: Air flow meter range: Gas flow meter range: Water flow meter range:

Raschig rings 10x10mm 0.15m³/[email protected] 10.0 l/min@3m 20-180 l/min 1.0-22.0 l/min 1.0-10.0 l/min

Air flow Pressure drop versus air flow for different flow rates

S1 KEY F = Flow meter S = Sample V = Valve

F3

F2

V10

V11

S2

F1

V

S1

S5

V9

S4

Gas cylinder and regulator not supplied Schematic diagram of mass transfer experiments

DISCOVER

WITH

Requirements Electrical supply: UOP7-A: UOP7-B: UOP7-G:

220-240V/1ph/50Hz 120V/1ph/60Hz 220-240V/1ph/60Hz

Water supply: 10L/min @ 1bar ESSENTIAL EQUIPMENT CO2 Cylinder with pressure regulator RECOMMENDED ANCILLARY EQUIPMENT Vent piping to outside laboratory Titration glassware for liquid analysis Separate drain tank for treatment of effluent OVERALL DIMENSIONS Height: Width: Depth:

2.53m 0.90m 0.65m

SHIPPING SPECIFICATION Gross weight 220kg Volume 2.0m3

OD

PR

R

TY

ON AL ARMF L

if you dispose of this data sheet please recycle it. Sourced from fully sustainable forests ISO 14001/TCF Certified

IEL

D

AR 2 -Y R W

2 years

AN

UCT S

<E X T E N D E D >

WARRANTY

Head Office: Armfield Limited Bridge House, West Street, Ringwood, Hampshire. BH24 1DY England Telephone: +44 1425 478781 Fax: +44 1425 470916 E-mail: [email protected]

© 2009 Armfield Ltd. All Rights Reserved

ORDERING SPECIFICATION • Floor mounted packed column gas absorption unit using a 80mm diameter, 1.4m long acrylic column. The column contains 7 litres of 10 x 10mm glass Raschig rings and is mounted in a steel frame • Pressure sensing and gas sampling points are sited at the top, centre and base of the column • Two manometers are included to measure pressure • A Hempl type gas analysis apparatus is included • Three variable area flow meters are included to measure the flow of gas, air and liquid • A rotary compressor is used to pump air into the column •W ater (solvent) is circulated using a centrifugal pump, using a 50 litre capacity feed tank • A comprehensive instruction manual is supplied which details the necessary installation, commissioning and maintenance procedures • The instruction manual also includes detailed experimental protocols for studying: o Principles of gas absorption into a liquid using a packed column o Methods of gas and liquid quantitative analysis o Mass balancing over a packed absorption column o Method of transferring units, including calculation of NTU and HTU o Determination of the mass transfer coefficient o Hydrodynamic characteristics of a packed column o Determination of loading and flooding points

U.S. Office: Armfield Inc. 436 West Commodore Blvd (#2) Jackson, NJ 08527 Telephone: (732) 928 3332 Fax: (732) 928 3542 E-mail: [email protected]

We reserve the right to amend these specifications without prior notice. E&OE 1109/3k/SO2796

Scan QR code* to the latest version of this datasheet

or click: www.armfield.co.uk/uop7

* S can with mobile smartphone or webcam with barcode scanning software installed.

An ISO 9001 Company

Innovators in Engineering Teaching Equipment

learn more! www.armfield.co.uk

UOP Series: Heat & Mass Transfer Operations

WITH

GAS ABSORPTION COLUMN – UOP7

© Armfield Ltd. 2009

DEMONSTRATION CAPABILITIES >S tudy of the basic principles of the absorption of a gas into a liquid using a packed column >D emonstration of methods of gas and liquid quantitative analysis > Production of mass balances for a packed absorption column

The Armfield Gas Absorption Column has been designed to demonstrate the principles of gas absorption and to provide practical training in the operation of gas absorption plant.

>M ethod of transferring units, including calculation of NTU and HTU > Determination of the Mass Transfer Coefficient > Study of the hydrodynamic characteristics of a packed column > Determination of loading and flooding points

R

TY

OD

PR

AR 2 -Y R W

2 years

AN

ON AL L ARMFIE

LD

The latest version of this data sheet is available at:

www.armfield.co.uk/uop7

UCTS

<E X T E N D E D >

WARRANTY

issue 11

Description The packed absorption column is made up of two 80mm diameter clear acrylic sections ed end to end and installed vertically on a mild steel floor standing framework. The column is filled with 10mm x 10mm glass Raschig rings, which are representative of the type of packing used in gas absorption. Liquid for the process is stored in a 50.0 litre rectangular feed tank and a centrifugal pump is used to deliver the liquid to the top of the column where it falls through the packing and returns to the tank. A variable area flow meter in the recirculation line gives a direct reading of flow rate.

Pressure tappings at the base, centre and top of the column are provided to allow indication of pressure drop in the column using manometers. These tappings also provide a means of extracting samples of gas from the column. Carbon dioxide content of the gas samples is determined using a Hempl apparatus. Flow meters, manometers and gas analysis equipment are all mounted on a vertical backboard at a convenient height for operation.

2.5 litres/min

et

ng

i od

s on

Flo

O

Pressure drop

The gas to be absorbed is normally carbon dioxide and would be taken from a pressure cylinder (not supplied), standing adjacent to the column. This gas es through a calibrated variable area flow meter and is mixed with an air stream also of known flow rate from a rotary compressor positioned in the framework. The ratio of gas to air in the mixture entering the column is therefore known and is easily varied. Entering at the base of the column, the gas mixture rises up through the packed bed and is counter-currently ed with the liquid flowing down the column.

4 litres/min

Gas

TECHNICAL DETAILS Feed tank capacity: Internal diameter of column: Volume of packing: Height of absorption column:

50.0 litres 0.80mm 7.0 litres 1.4m

Type of packing: Air compressor capacity: Column feed pump capacity: Air flow meter range: Gas flow meter range: Water flow meter range:

Raschig rings 10x10mm 0.15m³/[email protected] 10.0 l/min@3m 20-180 l/min 1.0-22.0 l/min 1.0-10.0 l/min

Air flow Pressure drop versus air flow for different flow rates

S1 KEY F = Flow meter S = Sample V = Valve

F3

F2

V10

V11

S2

F1

V

S1

S5

V9

S4

Gas cylinder and regulator not supplied Schematic diagram of mass transfer experiments

DISCOVER

WITH

Requirements Electrical supply: UOP7-A: UOP7-B: UOP7-G:

220-240V/1ph/50Hz 120V/1ph/60Hz 220-240V/1ph/60Hz

Water supply: 10L/min @ 1bar ESSENTIAL EQUIPMENT CO2 Cylinder with pressure regulator RECOMMENDED ANCILLARY EQUIPMENT Vent piping to outside laboratory Titration glassware for liquid analysis Separate drain tank for treatment of effluent OVERALL DIMENSIONS Height: Width: Depth:

2.53m 0.90m 0.65m

SHIPPING SPECIFICATION Gross weight 220kg Volume 2.0m3

OD

PR

R

TY

ON AL ARMF L

if you dispose of this data sheet please recycle it. Sourced from fully sustainable forests ISO 14001/TCF Certified

IEL

D

AR 2 -Y R W

2 years

AN

UCT S

<E X T E N D E D >

WARRANTY

Head Office: Armfield Limited Bridge House, West Street, Ringwood, Hampshire. BH24 1DY England Telephone: +44 1425 478781 Fax: +44 1425 470916 E-mail: [email protected]

© 2009 Armfield Ltd. All Rights Reserved

ORDERING SPECIFICATION • Floor mounted packed column gas absorption unit using a 80mm diameter, 1.4m long acrylic column. The column contains 7 litres of 10 x 10mm glass Raschig rings and is mounted in a steel frame • Pressure sensing and gas sampling points are sited at the top, centre and base of the column • Two manometers are included to measure pressure • A Hempl type gas analysis apparatus is included • Three variable area flow meters are included to measure the flow of gas, air and liquid • A rotary compressor is used to pump air into the column •W ater (solvent) is circulated using a centrifugal pump, using a 50 litre capacity feed tank • A comprehensive instruction manual is supplied which details the necessary installation, commissioning and maintenance procedures • The instruction manual also includes detailed experimental protocols for studying: o Principles of gas absorption into a liquid using a packed column o Methods of gas and liquid quantitative analysis o Mass balancing over a packed absorption column o Method of transferring units, including calculation of NTU and HTU o Determination of the mass transfer coefficient o Hydrodynamic characteristics of a packed column o Determination of loading and flooding points

U.S. Office: Armfield Inc. 436 West Commodore Blvd (#2) Jackson, NJ 08527 Telephone: (732) 928 3332 Fax: (732) 928 3542 E-mail: [email protected]

We reserve the right to amend these specifications without prior notice. E&OE 1109/3k/SO2796

Scan QR code* to the latest version of this datasheet

or click: www.armfield.co.uk/uop7

* S can with mobile smartphone or webcam with barcode scanning software installed.

An ISO 9001 Company

Innovators in Engineering Teaching Equipment

learn more! www.armfield.co.uk