Closed Conduit Flow Expt 6b6x6p

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report l4457

Overview 6h3y3j

& View Closed Conduit Flow Expt as PDF for free.

More details h6z72

- Words: 17,149

- Pages: 99

0

Page

CLOSED CONDUIT FLOW

“The wisest mind has something yet to learn.” George Santayana

Page

1

“The first great gift a teacher can bestow on his student is a good lab manual.”

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW ACKNOWLEDGMENT

We would like to thank all who helped and encouraged us to complete this laboratory manual; especially, our fluid mechanics professor, Prof. Cornelio Dizon for guiding us throughout our research work.

Also, special thanks to Kuya Cesar, Cesar Catibayan, who has guided us very well in handling the instruments used in this manual.

Page

2

Alvin Seria Imee Bren Villalba Jannebelle Dellosa Jaime Angelo Victor

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW TABLE OF CONTENTS

Page Introduction …………………………………………………………………………………………………..

4

Oil Pipe Assembly Experiment 1: Laminar and Turbulent Flow ……………………………………….

9

Air Pipe Assembly Experiment 2: Smooth and Rough Pipes …………………………………………….

24

Water Pipe Assembly Experiment 3: Minor Losses ……………………………………………………………….

38

Hydraulic Bench ................................................................................................

53

Experiment 4: Calibrating a Venturi Meter …………………………………………

58

Experiment 5: Calibrating a Flow Nozzle …………………………………………….

70

Experiment 6: Calibrating an Orifice Meter ………………………………………..

78

References …………………………………………………………………………………………………….

86

Appendix A: …………………………………………………………………………………………………….

87

Derivation of Bernoulli’s Equation Derivation of V-notch weir discharge equation Appendix B …………………………………………………………………………………………………….

92

Life and Works of Bernoulli Life and Works of Froude

Page

3

Life and Works of Reynolds

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW INTRODUCTION

There are two main classes of flow in fluid mechanics. The flow of fluids around bodies such as airfoils, rockets, and marine vessels is called external flow. This becomes the case when the other boundaries of the flow are comparatively distant from the body. One general type of this flow is open channel flow, also called free surface flow, wherein the fluid stream has a free surface exposed to atmospheric pressure, and gravity is the only component acting along the channel slope. This type of flow is encountered in natural bodies of water such as rivers, streams, and oceans, as well as in man-made hydraulic structures such as floodways, dams, and canals. On the other hand, flows that are enclosed by boundaries are termed internal flows. Examples of this type of flow include the flow through pipes, ducts, and nozzles.

This research paper focuses primarily on the latter class of flow, that is, the flow of fluids in closed conduits such as pipes. Different topics under this type of flow were discussed in detail. These topics include laminar and turbulent flow, circular and non-circular conduits, smooth and rough pipes, major and minor losses in pipes, single-pipe flow problems, series and parallel pipes, and branching pipes. Moreover, much attention is given to the detailed discussion of the different experimental apparatuses used in the study of flow in pressure conduits. Such apparatuses include the oil pipe ass embly, air pipe assembly, water pipe assembly, water tunnel, and hydraulic bench. Finally, different experiments that

Page

4

can be conducted using these facilities were also discussed thoroughly.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW INTRODUCTION

Page

5

Pipes are the most common tools used in the analysis of closed conduit flow. Usually, pipes used in engineering practice are long hollow cylinders; however, cross sections of a different geometry are used occasionally. Pipes can be smooth or rough, depending on the type of material from which they were constructed. There are commercially available pipes made of cast iron, galvanized iron, commercial steel, brass, lead, copper, glass, smooth plastic, and concrete, to name a few.

Figure 1. Type of commercial pipes

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW INTRODUCTION

Moreover, the pipe system will not be complete without pipe fittings. Pipe fittings or connections are used to different pipes, such as, bends, junctions, tees, etc. They are also used to control or alter the flow of the fluid through the pipe, this includes valves, gradual contraction and expansion, sudden contraction and expansion, bell-mouthed entrance and more others.

Laminar and Turbulent In 1883, Osborne Reynolds conducted an experiment on viscous flow. The results of his investigation showed that there are two distinct types of fluid flow, namely, laminar flow and turbulent flow. In his experiment, he allowed water to flow from a large tank to a long glass tubing (see Figure 1). An outlet valve was placed at the end of the tube to allow him to have complete control over the fluid velocity by varying the discharge out of the tube. At the entrance, he injected a very thin stream of colored liquid having the same density (or specific weight) as the water in the tank.

a.) Laminar Flow

Page

6

Figure 2. Reynolds Experiment

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW INTRODUCTION

With the outlet valve only slightly opened, that is, when the velocity of the liquid in the tube is small, he observed that the colored liquid moved in a straight line as illustrated in Figure 2a. As the valve was progressively opened, the velocity of the liquid in the tube gradually increased, and a fluctuating motion of the colored fluid was observed as it moved through the length of the tube (Figure 2b). Finally, when the valve was further opened, it was observed that the colored liquid is already completely dispersed at a short distance from the entrance of the tube such that no streamlines could be distinguished (Figure 2c). The type of flow illustrated in Figure 2a is known as laminar flow, also called streamline flow. Reynolds described it as a well-ordered pattern whereby fluid layers are assumed to slide over one another.. Figure 2b shows a transition flow from the previous laminar flow to an unstable type of flow. Finally, Figure 2c demonstrates a completely irregular flow called turbulent flow.

c.) Turbulent Flow

Page

7

b.) Transition Flow

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW INTRODUCTION

Energy Losses Fluid in motion offers frictional resistance to flow; wherein some part of the energy of the system is converted into thermal energy (heat). In fluid mechanics this converted energy is referred as “energy loss” or “head loss”. This energy loss is due to fluid friction as well as to valves and fittings. The former is more known as major losses; while, the latter as minor losses. The energy loss in long pipelines, with length to diameter ratio exceeding 2000, is mainly due to major losses, while minor losses are negligible. Otherwise, minor losses are dominant over minor losses in short pipelines.

Major Losses These are the energy dissipated through the walls of the pipe in which the fluid is flowing. Moreover, the magnitude of the energy loss is dependent on the properties of the fluid, the flow velocity, the pipe size, and smoothness of the pipe wall, and the length of the pipe.

Rough and Smooth Pipes As mentioned, major losses are dependent on the smoothness of the pipe wall. Pipe walls can either be rough or smooth depending on its material composition. For example a galvanized iron pipe is a type of a smooth walled pipe; while, a brass pipe is a rough walled pipe.

Minor Losses

Page

8

Elements that control the direction or flow rate of a fluid in a system typically set up local turbulence in the fluid, causing energy to be dissipated as heat. Whenever, there is a restriction, a change in flow velocity, or a change in the direction of flow, these energy losses occur. Moreover, in large systems the magnitude of losses due to valves and fittings is usually small compared to frictional losses; hence, they are referred as minor losses.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

Objective: 1.) 2.) 3.) 4.)

To determine the range of Reynolds number for laminar, transition and turbulent flow. To that the friction loss in laminar flow is equivalent to 64/Re. To the Hagen-Poiseuille equation. To determine the measurement uncertainties, and compare the results with benchmark data.

Introduction: Energy losses in closed conduits are classified into major and minor losses. Major losses result from the resistance of the conduit walls to the flow and minor losses are due to pipe appurtenances that cause a change in the magnitude and/or direction of the flow velocity. The determination of these losses is important for the specification of a pipeline design. Head losses mainly results from internal pipe friction when the ratio of the length of a pipeline to its diameter exceeds 2000 and minor pipe appurtenances are not present in a pipe. In this experiment, major losses are calculated and minor losses are assumed negligible. Theoretical background: The head loss for a pipe system is determined by the energy equation between two sections of the pipe given by P1/γ + Z1 + V12/2g = P2/γ + Z2 + V22/2g + HL

(1)

Page

9

Where P is the pressure at the centreline of the pipe, γ is the specific weight of the fluid, Z is the elevation of the centreline of the pipe relative to an arbitrary datum, V is the average flow velocity, g is the gravitational constant and H L is the total energy loss between section 1 and 2. When minor losses are negligible, HL is mainly due to frictional losses only.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

The velocity is determined when the discharge is known, using the equation Q = AV

(2)

Where Q is the discharge, A is the area of the pipe, and V is the velocity in the pipe. If the pressures at section 1 and 2 are known, the energy equation can be used to determine the head loss along the pipe. The pipe head loss due to friction is obtained using the Darcy-Weisbach equation: f = HL LV2 / 2Dg

(3)

Where f is the friction factor, L is the length of the pipe section, and D is the pipe diameter. The Moody diagram shows the relationship between the friction factor, relative roughness of the pipe and Reynolds Number. There are three zones of flow in the diagram, namely, laminar, transition and turbulent. Type of flow Laminar Transition Turbulent

Reynolds Number Re<2000 2000

<10^5 Re>10^5

Friction Factor f=64/Re f=0.316/Re^0.25 1/ =2.0log(Re ) – 0.8

The Reynolds Number is a dimensionless quantity used in the determination of the type flow. It is given as, Re=VD/ν (4) Where ν is the kinematic viscosity of the fluid. The Hagen-Poiseuille equation is used to describe slow viscous incompressible flow through a constant circular section. This equation can be derived from the Navier-Stokes equation given as, (5)

Where ΔP is the pressure drop and µ is the dynamic viscosity of the fluid.

Page

10

ΔP = 128µLQ/πD4

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

The energy grade line is a plot of the total head versus the length of the pipe. The total head is the sum of the pressure head, velocity head and elevation head at a particular point. The plot of piezometric head versus the length of the pipe is called the hydraulic grade line. The piezometric head is the sum of the elevation head and pressure head at a particular point.

Figure 1. EGL and HGL Apparatus:

Page

11

Oil Pipe Assembly

Figure 2. Oil Pipe Assembly

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

The experiment is conducted in an oil pipe assembly. The oil is pumped from the reservoir by the centrifugal pump. The gate valve controls the discharge from the upstream end of the section. Pressure taps are provided throughout the length of the pipe and connected to a manometer bank for head loss measurement. The pipe characteristics are provided below. The jet trajectory of the oil is observed at the transparent housing at the end of the pipe. At the downstream end of the system, the oil is collected in the weighing tank and the discharge is measured. The oil is then returned back into the reservoir. PARTS OF THE OIL PIPE ASSEMBLY

The test section of the oil pipe (Figure 3) assembly consists of a brass pipe about 5.80 meters long with an inside diameter of 21 mm, a transparent plastic section of about 30 mm in length with the same inside diameter, and a transparent housing at one end of the pipe. Figure 3. Test Section

Piezometer taps are provided throughout the length of the pipe and connected to a manometer bank (Figure 4) to measure the

Page

12

head loss.

Figure 4. Manometer Bank

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

A stagnation tube (Figure 5) is installed in the transparent section to measure the velocity profile.

Figure 5. Stagnation Tube

The housing at the end of the pipe (Figure 6) enables the observation of the

characteristics

of

the

jet

trajectory as the oil flow leaves the

Page

13

pipe.

Figure 6. Housing at the end of the pipe

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

The centrifugal pump (Figure 7), which draws the

oil from the

reservoir,

provides the flow of the oil in the test section is provided. Figure 7. Supply pump

The gate valve (Figure 8) which is located just after the pump adjusts the flow in the test section. In order to ensure the smooth entry of oil into the pipe, a bell shaped transition is fitted at the upstream end of the test section.

Page

14

Figure 8. Gate valve

Figure 9. Weighing Tank

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

The weighing tank (Figure 9) is used to measure the discharge by noting the time it takes to collect a certain amount of oil as it leaves the test section into the weighing tank at the downstream end. Oil which has accumulated in the weighing tank may be returned to the reservoir by means of the overflow conduit or by a quick-acting gate valve (Figure 10). This valve is linked to another quick acting valve in the supply line that would interrupt the flow into the test section while the weighing tank is being emptied. Figure 10. Quick Acting gate valve

The reservoir (Figure 11) is a place where oil is being stored. The oil used in the oil pipe assembly is transformer oil.

Page

15

Figure 11. Oil Reservoir

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

Figure 12. Piezometer taps in the oil pipe assembly

Piezometer taps are provided for measuring the head loss either by an oil manometer or a mercury manometer depending on the magnitude of the pressures. The location of these taps is provided in

Page

16

Figure 12.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

Procedure: 1. Determine the pipe diameter, dimensions of the pipe assembly, distance between taps and the type of fluid to be used. 2. Determine the density of the fluid by using a beam balance and graduated cylinder. The density is calculated using the following equation. (6) 3. Turn on the pump and check that the flow is following the correct path. 4. For each trial, set the flow rate to the desired flow of either laminar, transition, and type of flow is determined by observations of the jet trajectory.

(a)Laminar

(b)Transition

turbulent. The

(c)Turbulent

Figure 13. Jet trajectory for a) laminar, b) transition, and c) turbulent flow 5. Once the flow has stabilized, determine the discharge by getting the change in weight in the weighing scale over the time interval. Record the head loss across pipe length using the piezometer readings and the corresponding discharge. Record two readings of the piezometer for every discharge and get the average.

Page

17

5. The discharge, velocity and Reynolds Number are calculated using the following equations. Q=

(7)

Velocity =

(8)

(9)

6. Perform several trials.

Fluid Mechanics for Civil Engineering II

EXPERIMENTS Laminar and Turbulent Flow

Results: 1. Calculate the Reynolds number and then the friction factor. What type of flow is occurring within the pipe? 2. Using the results from (1) and the Darcy-Weisbach equation, compute the theoretical head loss for each flow rate. Quantitatively compare the theoretical values to your measured head loss data obtained using the differential manometer. Discuss your results. 3. Draw the energy and hydraulic grade lines for the different discharges. Qualitatively indicate elevation and pressure heads, but numerically identify the velocity head component of total energy and the head loss over the length of pipe. 4. Compute the discharge using the Hagen-Poiseuille equation and compare with the actual discharge.

Page

18

5. that for a laminar flow, the friction loss is equivalent to 64/Re.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

Table 1.Data Sheet:

Discharge Trial No.

PRESSURE MEASUREMENTS (mm) 1

LAMINAR

1

2

3

4

5

6

7

8

9

10

reading 1 reading 2 Average

2

reading 1 reading 2 Average

TRANSITION

3

reading 1 reading 2 Average

4

reading 1 reading 2 Average

TURBULENT

5

reading 1 reading 2 Average

6

reading 1 Average

Page

19

reading 2

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

Table 2.Discharge and Reynolds Number Computation Discharge No.

ΔWeight (lbs)

ΔWeight ΔVolume ΔTime Discharge Velocity Re 3 3 (kg) (mm ) (s) (mm /s) (mm/s) DV/ ν

Reading 1 1

2

Reading 2 Average Reading 1 Reading 2 Average

3

Reading 1 Reading 2 Average

4

Reading 1 Reading 2 Average

5

Reading 1 Reading 2 Average

Page

20

6

Reading 1 Reading 2 Average

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

Sample data and Calculation: Table 3. Properties of the fluid and pipe diameter of pipe (mm) area of pipe (mm2) e (mm)

26.8

0.001524

e/d ν (mm2/s) μ (kg/mm-s)

5.69E-05 16.5 1.42E-05

564.1

Table 4.Computation for the fluid density Trial 1 Wt. of graduated cylinder (g) Wt. of Oil + graduated cylinder(g) Volume (mL) Wt. of Oil (g) ρ (kg/mL) ρ (kg/m3) ρ (kg/mm3)

Trial 2

Average

115 179.5

170.9

75 64.5 0.00086 860 8.6E-07

65 55.9 0.00086 860 8.6E-07

0.00086 860 8.6E-07

Table 5.Sample data for discharge trial 1 PRESSURE MEASUREMENTS (mm) Discharge Trial No.

1

Reading 1 Reading 2 Average

2 580 600 590

3 555 555 555

4 430 420 425

5 340 340 340

6 225 225 225

7 -

8 90 80 85

9 -

10 -

Page

21

LAMINAR

1 680 670 675

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

Table 6.Sample Calculation for discharge trial 1 Discharge No.

1

ΔWeight (lbs) reading 1 reading 2 average

ΔWeight ΔVolume (kg) (mm3) 220 224 4

1.814

2109302

ΔTime (s)

Discharge Velocity Re 3 (mm /s) (mm/s) DV/ ν

8 7.5 7.75

272168

482

784

Table 7.Sample Calculation for discharge trial 1 using Hagen-Poiseuille equation

πD4 /128μ = 879027684.3 kg5 /mms p/γL p/L 0.1405

0.001184

Q from HP equation (mm3/s) 572488

Qexpt (mm3/s)

Deviation (%)

272168

52%

Extension Experiment

Page

22

Experiments on velocity distribution for laminar flow maybe conducted on the oil pipe assembly where a stagnation tube is provided in the transparent test section. The experimental programs should consider of such parameters as the location where the velocity is measured and the Reynolds number. The position of the stagnation tube may be may moved vertically along the diameter of the pipe and its location is measured by the vernier attached. Stagnation pressure may be measured by an oil manometer or by a mercury manometer depending on the magnitude of the pressure. The static pressure may be determined from the values of the pressures upstream of the stagnation tube. The velocity and Reynolds number may be varied by changing the discharge.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Laminar and Turbulent Flow

For laminar flow, the velocity distribution may be determined using the equations of motions on a free-body diagram of a fluid element where the shearing stresses are formulated in accordance with Newton’s Law of Viscosity. The result is a parabolic distribution, which for a horizontal pipe is as follows, u= (ro2-r2/4µ)(dp/dx) (10) Where u is the velocity at a distance r from the centerline, ro is the radius of the pipe, µ is the dynamic viscosity, and dp/dx is the rate of pressure drop. In of maximum velocity (umax) at which r=ro, the velocity distribution may be written as follows: u = umax (–r2/4µ)(dp/dx) (11)

Figure 14.Velocity distribution for fully developed laminar flow

Page

23

Analysis of the experimental values may be correlated with the analytical values. One way of plotting the experimental results is shown below.

Figure 15.Velocity distribution on pipes for laminar flow

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes

Objective 1. To develop velocity distribution, to calculate head losses (frictional losses), and to prove the validity of Reynolds Number in smooth and rough pipes using the air pipe assembly. 2.To compute actual friction factors and to compare these values from the theoretical values found in the moody diagram. 3. To the Nikuradse equation. 4. To aim to plot the energy and hydraulic grade lines along the length of the pipe.

Introduction Pipes are closed conduits used to convey fluids. Usually, pipes used in engineering practice are long hollow cylinders; however, cross sections of a different geometry are used occasionally. Pipes can be smooth or rough, depending on the type of material from which they were constructed. Commercially available pipes are made of cast iron, galvanized iron, commercial steel, brass, lead, copper, glass, smooth plastic, and concrete, to name a few. For a simple pipe without a pump or turbine, the increase in the total mechanical energy of the fluid, between any two selected sections of the pipe, is equal to the energy dissipated in head loss. The head loss, in this case, can be subdivided into two categories: major losses and minor losses. Major losses are those caused by pipe or wall friction; while minor losses include those losses due to changes in pipe cross section, and the presence of pipe fittings, bends and elbows along the pipe length.

hf = f (L/D) (V2 / 2g)

Page

24

If the pipe is of constant cross section throughout its length, and if there are no pipe fittings, bends, or elbows, then the friction losses become the total head loss in the pipe. From several experiments, it was proven that the friction inside the pipe does not only depend on the shape and size of the projections on the internal pipe wall, but also on their distribution. The friction loss can be determined using the formula

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes All the variables in the previous formula, except for the friction factor f, can be easily determined experimentally. Many people have tried to developed different approximations and expressions to compute for the friction factor of a pipe. The knowledge of the friction factors of pipes is essential to the design of water projects such as drainage systems, and other pipe network projects. The fluid friction can dissipate energy, thus reducing extra turbulence of the fluid. The main purpose of this experiment is to be able to compute the friction factor of a smooth pipe (made of brass) and a rough pipe (made of galvanized iron), and to compare these experimental values to their theoretical values. Moreover, the plot of the hydraulic and energy grade lines of the pipe is to be obtained. With the use of the Air Pipe Assembly, essential quantities such as fluid discharge and pressures shall be measured. With the concepts of fluid flow, basics of fluid statics, energy equations for steady flow, and the fundamentals of steady incompressible flow in pressure conduits, all the other important but unknown quantities shall be calculated, including the friction factor. Finally, it shall be realized that the friction factor for rough pipes is larger compared to that for smooth pipes.

Theoretical background If the head loss in the pipe is mainly due to friction, another expression for the head loss will be hL = f (L/D) (V2 / 2g)

= friction factor of the pipe L = length of the pipe D = diameter of the pipe V = velocity of the fluid inside the pipe g = acceleration due to gravity, equal to 9.81m/s 2

Equation (1) is called the Darcy Weisbach Equation, and is derived using dimensional analysis.

Page

25

where, f

(1)

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes The friction factor f is a dimensionless number, and is a function of the Reynolds number and relative roughness, defined as the absolute roughness divided by the pipe diameter, of the pipe. The friction factor can be determined by rearranging equation (1) to obtain an expression for f in of the other variables. Thus we have, f = hL D (2g) / L V2

(2)

The head loss hL can be calculated using Δ(P/γ); the fluid velocity V, using the continuity equation ; and the pipe diameter D and the pipe length L are readily available. To determine the theoretical value of the friction factor, the equation derived by Haaland can be used, that is, 1/sqrt (f) = -1.8 log {[(ε/D) / 3.7]1.11 + 6.9 / Re}

(3)

Equation (4) is valid for turbulent flow in all pipes, and is applicable for fluids having a Reynolds number greater than or equal to 4000 but less than or equal to 108. Other equations that can be used to calculate the friction factor of pipes are as follows: For smooth pipes 1/sqrt (f) = 0.869 ln [Re sqrt (f)] – 0.80

(4)

For rough pipes 1/sqrt (f) = 1.14 + 0.869 ln (e/D)

(5)

Page

26

Equations 4 and 5 are Nikuradse equations for smooth and rough pipes, respectively.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes The Moody Diagram The Moody diagram is named after L.F. Moody, who worked with C.F. Colebrook to correlate the correlate the original data of Nikuradse in of the relative roughness. Based on the Moody Diagram (in a fully developed pipe flow), the friction factor, f, depends on Reynolds number, Re, the roughness, ε, the pipe diameter D, and thus, on relative roughness, ε/D of the pipe

Page

27

Figure 1. Moody Diagram Source: http://web.deu.edu.tr/atiksu/toprak/muabak.gif

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes

Table 1. Absolute roughness of different pipe materials Pipe Material

Absolute Roughness, ε x 10-6 feet micron (unless noted) drawn brass 5 1.5 drawn copper 5 1.5 commercial steel 150 45 wrought iron 150 45 asphalted cast iron 400 120 galvanized iron 500 150 cast iron 850 260 wood stave 600 to 3000 0.2 to 0.9 mm concrete 1000 to 10,000 0.3 to 3 mm riveted steel 3000 to 30,000 0.9 to 9 mm *Page 476, Fundament als of Fluid Mechanics 4th Edition - Munson - John Wiley and Sons

Relative pipe roughness is computed by dividing the absolute roughness e by the pipe diameter D,

Page

28

It can be inferred from the Moody chart that for laminar flow, f=64/R e . For moderate values of Reynolds number (2,100 < Re < 4000), the flow may be considered as laminar or turbulent, based on the actual situations. The friction factor in this case is a function of the relative roughness and Reynolds number, that is, f= Ø(R e , ε/D). However, for large enough Re, the friction factor is solely dependent on the relative roughness. Thus, f= Ø(ε/D). Such flows are called completely turbulent or wholly turbulent flow. For pipes which are very smooth (ε=0), due to microscopic surface roughness, there is still head loss in the pipe. Hence, the friction factor in a very smooth pipe is not zero.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes

Apparatus An Air Pipe assembly is an instructional apparatus with a system of smooth and rough pipes with pressure taps along its length to facilitate pressure drop measurement.

Brass Pipe

Galvanized Iron Pipe

Piezometer Taps

Valves Manometer Bank

Venturi Meters

Figure 2. Schematic Diagram of the Air Pipe Assembly

In an experiment that will use an Air Pipe facility, there will be three different test pipes that can be investigated, where all pipes are approximately 8.94m in length. This portion of the equipment consists of a 125mm and a 500mm diameter Galvanized Iron (GI) pipe, and a 500mm diameter brass pipe. The relative roughness for the brass pipe and galvanized iron are 0.0015mm and 0.15mm, respectively.

Page

29

In this set-up, pressure built in a large reservoir forces air to flow through a chosen straight experimental pipe. The blast gate set between the compressor and the tank regulates the discharge through the system. Discharge through the experimental pipes is measured by the Venturi meters installed between the fluid source and the pipes. There are six gate valves that may be used to direct fluid flow. The three upper valves manage flow through the experimental pipes, the other three valves on the lower portion of the apparatus is used to select which Venturi meter will be appropriate to use.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes

Figure 3. (a) the Control Valves for the system, (b) the Venturi Meter, (c) the reservoir, control knob, and blower

A number of piezometer taps are installed in the pipes to allow head measurement, specifically, pressure drops along the pipe length. These taps are connected to a manometer bank where readings are obtained. The first 12 manometers (Numbered 1-12) are for readings for the brass pipe, the following 12 (Numbered 13-24) are for the galvanized iron pipe. Venturi readings are taken from manometers numbered as 26-31.

(a)

brass pipe

Page

30

Figure 4. Distance between taps

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes

(b)

GI pipe

Figure 5. Manometer Bank

Page

31

In a typical experiment, different discharges per trial will be considered. It must be assumed that discharge is constant throughout the system.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes Procedure Experimental Procedure: 1. For one trial, consider a constant discharge by selecting a fraction of the total opening using the control valve. 2. Choose which Venturi meter is appropriate to use. Once one is chosen, open fully the gate valve controlling the flow through that Venturi meter and tightly close the valves of the other two. 3. Open fully the gate valve controlling flow in the brass pipe. Make sure that the valve for controlling flow in the galvanized iron pipe is tightly closed. 4. Obtain manometer readings of the brass pipe from those labelled 1-12. 5. Open fully the gate valve controlling flow in the galvanized iron pipe. Make sure that the valve for controlling flow in the brass iron pipe is tightly closed. 6. Obtain manometer readings of the galvanized pipe from those labelled 13-24. 7. Obtain the manometer readings corresponding to the Venturi meter being used from those labelled 26-31. 8. Perform the same procedure above using 10 trials of different discharges. Computational Procedure: Experimental (Actual) Data: 1. For each trial, apply the Energy Equation between each tap of the pipes to solve for the head loss along the pipe, considering only frictional losses and neglecting minor losses. 2. Solve for the actual friction factors of the pipes using the Darcy Weisbach Equation, given the diameter and length of the pipe, and the velocity obtained through the Continuity Equation.

Page

32

3. Obtain the average value of the friction factors.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes

Theoretical Data: 1. Compute Reynolds Number for the pipe flow 2. Given the relative roughness of the brass and galvanized iron pipe, obtain the theoretical friction factors of the pipes using the Moody diagram. 3. Compare these theoretical values with the actual friction factor values. 4. For flow with Reynolds number greater than or equal to 4000 but less than or equal to 10 8, check whether or not the Haaland Equation is verified. 5. Alternatively, check whether or not the Nikuradse Equations for smooth and rough pipes are verified.

Page

33

6. Plot the Energy and Hydraulic Grade lines for each pipe.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes Table 2.Data sheet Manometer Readings for the Pipes Discharge

Venturi Readings

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

*

*

Trial 1

Trial 2

Trial 3

Trial 4

Trial 5

Trial 6

Trial 7

Trial 8

Trial 10

Page

34

Trial 9

*Manometer corresponding to the chosen Venturi meter

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes

Sample Data and Calculation Table A.1 Experiment Data Sheet: Smooth and Rough Pipes

Trial

1

Valve Opening

1/16

Pipe Brass GI Brass Pipe GI Pipe

1 19

Piezometer Reading (mm) 2 3 4 5 6 20 21 22 23 24

358

378

391

407

423

438

-

352

372

386

389

405

427

-

7 25

Venturi Meter Readings Inlet Throat 198

362

Discharge (cms) 0.025622725

Table B.1 Brass Pipe Trial

Taps

Length(m)

1

2-3 3-4 4-5 5-6 2-6

2.058 1.982 1.982 1.982 8.003

Headloss (m) 10.759 13.241 13.241 12.414 49.655

Velocity (m/s) 13.057 13.057 13.057 13.057 13.057

Frictio n 0.030 0.038 0.038 0.036 0.036

Reynolds number 43524.692 43524.692 43524.692 43524.692 43524.692

1/SQRT(F) 5.766 5.100 5.100 5.267 5.293

0.869ln(R*sqrt(f)) -0.80 6.959 7.066 7.066 7.038 7.034

%difference 17.15 27.82 27.82 25.16 24.76

Questions 1. Explain why the valve controlling the pipe where readings are obtained should be fully opened while the valve of the other pipe should be fully closed. 2. Enumerate the possible sources of errors in the experiment

Page

35

Extension experiments

Using set-ups such as like the one described above tends to be error-prone at times. A common source of error may be described as a situation wherein pipes increase their actual friction factors due to imperfections inside the pipe such as dirt and other particulates. Aged pipes typically exhibit rise in apparent roughness. Leakage in the manometer bank also greatly affects the readings. Modern Air Pipe Facilities have now refrained from taking measurements manually. Instead, they use the Automated Data Acquisition System (ADAS).

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes

Source: http://www.engineering.uiowa.edu/~fluids/Lab-documents/EFD/EFD%20Lab2/lab2.pdf

Page

36

Automated Data Acquisition System (ADAS) Configuration The ADAS is used to acquire pressure measurements electronically. The system is generally composed of a computer connected to an analogue to digital converter and a pressure sensor (transducer). The current experimental setup has two data acquisition systems. ADAS 1 is connected to the smooth pipe and ADAS 2 is connected to rough pipe. The LabView, developed by the American company National Instruments (NI), is the program used to facilitate sequential data collection in a uniform manner.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Smooth and Rough Pipes 1 2 3 4 5 Fixed Metal Plate

Low Pressure

LabView Program

Capacitanceto-Voltage Conversion

T

Capacitor, C

To Pressure Transducer Display E

Data Store

Analog to Digital (A/D) Board

Flexible Metal Diaphragm High (Deflects Under Pressure Pressure 6 Difference) 7 8

Figure 5. Schematic Diagram of ADAS General ADAS software commands or window labels:

Page

37

DPD menu measures the discharges DPF measures the pressure drop along the pipe length DPV measures the pipe velocity profiles A/D interface allows specifying the operation parameters.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Objectives: 1. To comprehend the principle behind the energy equation 2. To recognize the sources of minor losses 3. To be able to determine head losses and also to establish the friction coefficients of the corresponding and the pipe fittings Introduction: The first law of thermodynamics, the law of conservation of energy states that energy is neither created nor destroyed, it can only transform from one guise to the other. Universal as it is, the hydraulic system is of no exemption. Wherein given a hydraulic system, the total energy at one section is equal to the total energy at some other section within the system. In other words, the sum of the energies in the system is a constant. More often, it seems that energy is reduced or lost after undergoing a process; on the other hand, the apparent lost energy is actually converted into heat and released to the environment. This energy conversion is mainly caused by friction.

Application: Understanding this principle is useful in constructing optimum water system designs. Some of which are as follow,

Page

38

It enables accurate selection of appropriate size and required number of pumps to be used in a municipal water distribution system. It can serve as a guide in selecting conduit sizes for a gravity-flow urban drainage project. It can help identify the optimum size of valves and the radius of curvature of elbows to fit the specifications of a pipeline designs.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Theoretical Background: In hydrodynamics, fluids are assumed to be subjected to certain laws of physics; wherein one of which is the law of conservation of energy. This was first recognized by Daniel Bernoulli (Switzerland, 17001782), and formed the basis for the Bernoulli’s equation . Bernoulli’s equation: p 2A2 p 1 v 12 p 2 v 22 z1 z2 H 2g 2g 1g 2g ( 1) L

Where, P – Pressure Ρ – Fluid density g – Acceleration due to gravity 9.81 m/s 2 (S.I.) 32.2 ft/s2 (English system) v – Average velocity H – Total hydraulic energy

z2

p 1A1 z1 Da tum

Illustration 1. Control volume

Moreover, all the constituent parts of the equation have units of length; hence, each term may be regarded as ‘head’. Specifically, p Pressure head g v2 Kinetic or velocity head 2g Z Potential or elevation head

Page

39

The Bernoulli’s equation assumes that the fluid flowing is incompressible and no energy is supplied nor extracted during the age from entry to exit. Hence, energy entering = energy leaving

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Moreover, it also implies that the fluid is frictionless. If this were not so, frictional forces would transform some of the energy into heat. Thus, there would be ‘loss’ between 1 and 2 (refer to Illustration 1). To for this energy loss, the Bernoulli equation is transformed into the energy equation,

v 12 z1 2g

p1 1g

p2 2g

v 22 z 2 hL 2g

(2)

Where, hL is the head loss due to friction. Moreover, energy losses consist of major losses and minor losses. Major losses result from the resistance of the conduit walls; while, minor losses or local losses result from pipe appurtenances, such as bends, junctions, and valves, which cause the flow velocity to be changed in magnitude and/or direction. Also, these losses are due to eddy formation generated in the fluid at the fittings. In case of long pipelines the minor losses may be negligible, but for short pipelines, they may be greater than the major frictional losses. Minor losses are expressed in the simple equation,

hl k L

v2 2g

(3)

Where, hl is the minor head loss and kL is the constant dimensionless head loss coefficient of pipe fittings. The actual value of kL is strongly dependent on the geometry of the fixtures being considered. As for cases of sudden enlargement or sudden contraction, kL may be derived from the expression of the area of the pipe. While, for all other cases, such as bends, valves, and junctions, the values of kL are derived experimentally.

hl

8k L Q2 2 4 g D

(4)

Page

40

Another way to express the minor loss equation in of the discharge,

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Where, Q is the discharge and D is the diameter of the pipe. Moreover, minor losses can also be converted into equivalent lengths of pipe having the same effect. k LD L equivalent f (5) Where, f is the friction factor determined for the pipe flow. Apparatus: Water Pipe Assembly

Page

41

Figure 1. Water Pipe Assembly (Left side view)

Figure 2. Water Pipe Assembly (Right side view)

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Water circulates from the laboratory’s constant head tank to the pipe system and back to the main reservoir. Moreover, desired flow rates are attainable by adjusting the appropriate valves, such as, the main valve, the head tank valve as well as the valves forming part of the pipe fittings.

Figure 3. Main valve

Figure 7. Valves as pipe fitting

Page

42

Figure 4. Head tank valve

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Page

43

Figure 8. Test section

Moreover, the water pipe assembly’s test section consists of two parallel pipe lines of varying diameter and interconnected by various types of pipe fittings.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Pipe Line #1

Illustration 2. Pipe line #1 * Piezometer taps a re indica ted by enci rcled numbers *Di mensions a re gi ven in centimeters

Pipe Line #1 consists of the following pipe fittings: A – Bell mouthed entrance

E – Long radius elbow

B – Gradual enlargement

F – Long radius double tee

C – Gradual contraction

G – 5 cm diameter gate valve

Page

44

D – 5 x 4 Venturi meter

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Pipe Line #2

Illustration 3. Pipe line #2

* Piezometer taps a re indica ted by enci rcled numbers *Di mensions a re gi ven in centimeters

Pipe Line #2 consists of the following pipe fittings: H – Sharp edged entrance

L – Standard 90° elbow

I – Sudden enlargement

M – Standard tee

J – Sudden contraction

N – 2” Globe valve

Page

45

K – Orifice between flanges (1⅝” diameter)

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses Pipe fittings

Gradual enlargement (upper pipe) Sudden enlargement (lo wer pipe)

Gradual contraction (upper pipe) Sudden contraction (lower pipe)

5 x 4 Venturi meter (upper pip e) Orifice between flanges (lower pipe)

Long radius elbow (right pipe) Standard 90° elbow (lower pipe)

Standard tee

Long radius double tee

Gate valve (right pipe) Globe valve (left pipe)

Page

46

Bell mouthed entrance (upper pipe) Sharped edged entrance (lower pipe)

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Piezometer taps are also provided upstream and downstream of the pipe fittings to measure the head loss. These piezometer taps are brought in pairs to a manometer board containing differential manometer with Carbon Tetrachloride as fluid.

Figure 9. Manometer board

Figure 10. Manometer pairs

For analysis, the connections of the piezometer taps from the test section to the manometer pairs can be simplified into Illustration 4. Whereby, points A and B are the piezometric taps located at the upstream and downstream of the pipe fitting, respectively.

Page

47

Using the differential manometer

Illustration 4. Sample section

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses Solving for the pressures at point A and B,

pA

h

h

1 1

2 2

1

( h1 h2 )

pB

(6)

Simplifying the equation,

pA

pB

h2 (

2

1

)

(7)

Where, pA and pB are the pressures at point A and point B, respectively; while, γ1 and γ2 are the specific weights of the flowing fluid and the gage fluid. In this experiment, the flowing fluid is water and its specific weight is 9810 N/m3. Also, the gage fluid is carbon tetrachloride and its specific weight at room temperature (25°C) is 15542.87 N/m3. Moreover, h2 is the difference between the manometer reading of point A and B and it is denoted by Δh. Hence,

pA p

pB

h( 5732 .87 )

h( 5732.87 )

(8) (9)

Moreover, when the pipe lies on the same elevation, z 1 = z2; hence, the elevation head of the Bernoulli’s equation cancels out. p1 g

v12 2g

v22 2g

p2 g

hL

(10)

Arranging the , the equation for the head loss is hL

Page

48

hL

p1

p2

v12

v12

v 22 2g

g h

v 22 2g

(11)

Using the continuity equation, the mean velocity can be derived by using the equation, V=Q/A or V=4Q/ D4, where D is the diameter of the pipe. Also, if the diameter of the pipe is constant, the velocity head is equal to zero.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses hL

h

(12)

Furthermore, the water pipe assembly also has two identical 60° triangular weir to measure the discharge. Also a calibrated point gauge (stilling well) is attached to each tank to measure water elevations in the tank. The crest elevation is measured by allowing the tank to drain to the level of the crest (vertex). Also, by subtracting the crest elevation from that of the water surface gives the depth of the flow H in feet. The equation for the discharge is expressed as, 5

Q

1.434 H 2 (cfs)

(13)

Page

49

Figure 11. V-notch weirs

Figure 12. Stilling well

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses

Using the continuity equation (Illustration 5), Qin

Qout

Q

Qleft

Hence,

Qright

(14)

Procedure: 1. Open the main valve and the head tank valve 2. Let the water flow until it overflows the tanks containing the weir 3. Close the main valve, and let the water drain from the weir 4. Using the calibrated point gauge, measure and record the bottom of the stilling well and also the height of the water contained for each of the weirs 5. Open the main valve 6. Once the water is flowing, fully open the valves in pipeline #1 7. Wait for the flow to be stable, then measure and record the height of the water surface flowing from each weir 8. Record the readings on the manometer board (47 – even numbers). 9. Close all the valves of pipeline #1 10. Fully open all the valves in pipeline #2 11. Repeat step 7 12. Repeat step 8 (47 – odd numbers) 13. Adjust the appropriate valves to select and change discharge 14. Repeat step 6 to 12

Page

50

Illustration 5. Discharge in tee connection

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses WORKSHEET Left Weir

Right Weir

Left weir

Right weir

Bottom of the stilling well (ft) Height of the crest (ft)

Pipeline #1 Height of the water (ft) H (ft) Discharge (cfs) Sum of the discharges (cfs)

Taps#

Manometer Reading (in)

Head Drops Pressure Head (in)

Velocity Head (in)

Elevation Head (in)

Head Loss (in)

v2 2g

kL

47 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32

Page

51

34 36 38 40 42 44 46

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Minor Losses Pipeline #2 Left weir

Right weir

Height of the water (ft) H (ft) Discharge (cfs) Sum of the discharges (cfs) Taps#

Manometer Reading (in)

Head Drops Pressure Head (in)

Velocity Head (in)

Elevation Head (in)

Head Loss (in)

v2 2g

kL

Page

52

47 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW APPARATUS The Hydraulic Bench

Page

53

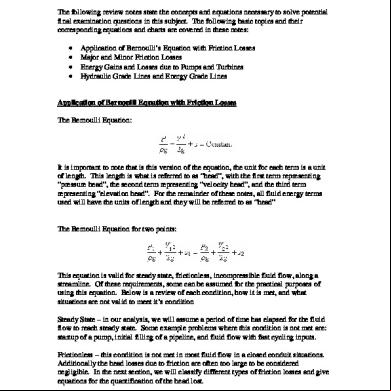

The hydraulic bench (see Figure 1) is a simple apparatus designed to provide a clear demonstration of some of the more common fluid flow phenomena. With this device, a number of experiments on closed conduit flow can be conducted. These include determining the head losses in pipe transitions, establishing the pressure distribution along the pipe, calculating the changes in the fluid pressure due to varying pipe cross section, calibrating flow meters, and a lot more.

Figure 1. The Hydraulic Bench

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW APPARATUS The Hydraulic Bench A pump (see Figure 2) from the reservoir to the head tank of the experimental units provides the flow of the fluid in the hydraulic bench. The rubber tubing shown in figure N connects the reservoir to the tank.

Figure 2. The pump

A butterfly valve located inside the supply line/tube controls the flow of the liquid from the reservoir to the head tank of the experimental unit being used. The handle (shown in figure 3) shows the position of the valve.

Figure 3. The butterfly valve

Page

54

Figure 4 shows a closed valve. To allow the liquid to through, turn the handle in a clockwise direction. The discharge of the liquid is maximum when the handle is vertical.

Figure 4. The valve handle

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW APPARATUS The Hydraulic Bench

Figure 5. The volumetric tank

The discharge of the fluid may be measured using the 35cm x 30cm x 34cm volumetric tank, shown in Figure 5, located on top of the reservoir. This is accomplished by noting the change in the volume of the fluid in the tank for a certain time interval.

Figure 6. The piezometric tube

The cross section of the tank is constant along its height; thus, discharge measurement can also be done by simply considering the change in the water level in the tank for a certain time interval. The change in water level can be read from a piezometric tube on one side of the tank (refer to Figure 6).

Figure 7. The drain orifice

Page

55

The liquid flows from the test section to the volumetric tank via the orifice shown in Figure 7.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW APPARATUS The Hydraulic Bench

The liquid is directed to or away from the tank by a swing-type inflow valve that is operated using the built in T-shaped control shaft, shown in Figure 8.

Figure 8. The swing-type inflow valve

Figure 9 shows the crankshaft mechanism of the swing–type valve. With this configuration, the liquid is directed towards the volumetric tank.

Figure 9. Water flowing to the tank

Page

56

On the other hand, Figure 10 shows the valve with the liquid directed away from the volumetric tank. The tank is drained by means of an orifice at the bottom, which is automatically activated when the flow is directed away from it.

Figure 10. Water flowing away form the tank

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW APPARATUS Experimental Units There are three experimental units that may be used with the hydraulic bench. One of these is shown in Figure 11. It consists of two head tanks, a set of piezometer tubes, and a glass tube with a venturi meter slot. The primary function of this unit is for the calibration of venturi meters. With the measured discharge of the liquid using the volumetric tank, and the theoretical equation for the discharge through a venturi meter, the coefficient of discharge for any venturi meter size can be obtained.

Figure 11.

Another unit is shown in Figure 12, consisting of a constant head tank and a circular opening on the lateral area of the tank. This is used in the analysis of the behavior of free jets. Moreover, it can also be used to calibrate orifices. With the Bernoulli equation, the theoretical velocity of a fluid particle can be calculated. Applying the principles of projectile motion, the actual velocity of the liquid can be obtained. With these two values, a coefficient of velocity for a certain orifice can be determined. The theoretical discharge can also be calculated by multiplying the theoretical velocity with the area of the orifice. With the actual discharge measured using the volumetric tank, the coefficient of discharge can also be calculated.

Page

57

The third experimental unit is shown in Figure 13. This is used in the study of impact jets.

Figure 12.

Figure 13.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter Objectives: 1. To calculate the coefficient of discharge of a venturi meter 2. To plot the discharge vs. pressure drop (Q vs. H) curve for a venturi meter 3. To plot the coefficient of discharge vs. Reynolds number (C d vs. Re) curve for different actual discharges

Introduction: Flow meters are devices used for measuring fluid flow rate, whether it is in closed conduits or in open channels. There are two basic types of flow meters: those that measure quantity, and those that measure rate. Measurements of quantity are obtained by counting successive isolated portions of flow. On the other hand, measurements of rate are determined f rom the observed effects on a measured physical property of the flow. Rate meters are devices used to measure the fluid flow rate as either volume per unit time or as mass per unit time. One type of rate meter, placed directly in the flow line of closed conduits, introduces a flow constriction that causes a decrease in pressure that is dependent on the rate of flow on the constriction. This device is first known as the venturi tube, named after Giovanni B. Venturi, an Italian Physicist who investigated its principles during the early 18th century.

Page

58

The venturi tube consists of an upstream section attached to the pipeline, and a converging section that leads to a restriction or a smaller diameter pipe. This convergent zone is efficient in converting pressure head to velocity head. Then, a divergent section is connected downstream to the pipeline, converting the velocity head back to pressure head with slight friction loss. Piezometer tubes or static pressure taps are attached at the upstream section and at the throat of the venturi tube. These are then attached to the two sides of a differential manometer to easily measure the pressure difference between the two points. Since there is a definite relation between the pressure drop and the discharge of the fluid, the tube may be made to serve as a metering device called the venturi meter.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter The main purpose of this experiment is to calibrate a venturi meter by determining its coefficient of discharge. This can be done by constructing the calibration curve, that is, the discharge versus pressure drop curve, for the venturi meter. Moreover, a plot of the coefficient of discharge versus the Reynol ds number is to be obtained. At the end of the experiment, it shall be realized from the graphs that the venturi meter is most accurate for large discharges. Theoretical Background: Figure 14 shows a cross section of the venturi meter with a differential manometer attached to it. The zone enclosed by polygon abcd is the control volume since it contains the points of interest, point 1 and point 2, where the pressure difference is measured.

Figure 14. The venturi meter

Considering the fluid to be incompressible, the continuity equation applied to the control volume gives (1)

From Figure 14, A1 is larger than A2; thus, equation (1) implies that V 1 should be less than V2.

Page

59

Q = A1V1 = A2V2

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter Consequently, the flow velocity must increase at the throat. Assuming no friction losses through the venturi meter, the Bernoulli equation applied from point 1 to point 2 yields ( P1/ γ ) + z1 + ( V12 / 2g ) = ( P2 / γ ) + z2 + ( V22 / 2g ) Where,

(2)

P1 and P2 = pressures at area points 1 and 2, respectively z1 and z2 = elevation heads of points 1 and 2, respectively V1 and V2 = velocities of points 1 and 2, respectively γ = unit weight of the fluid in the venturi meter g = acceleration due to gravity

Theoretically, the pressure in a fluid decreases with increasing velocity. As a result, there must be a pressure drop existing in the venturi meter from point 1 to point 2. Rearranging equation (2) in such a way that velocities are separated from the other quantities, we get

(3a) Using equation (1), equation (3a) can be modified to

3b)

A2 / A1 = D24 / D14

(4)

Page

60

Solving for the volumetric flow rate Q in of the other variables, and noting that

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter

Equation (5) is the theoretical equation for the discharge through the venturi meter for frictionless incompressible flow. The manometer reading provides the pressure drop ( P 1 – P2 )/γ required in equation (5). From the differential manometer in figure N, we see that the fluids at points 1 and 2 are the same; thus, they have the same density. From hydrostatics, proceeding from point 1 through the manometer tubing to point 2 gives P1 – γ1h1 – γ2H + γ1h2 = P2 (6) Where

P1 and P2 = pressures at points 1 and 2, respectively γ1 = unit weight of the fluid in the venturi meter γ2 = unit weight of the fluid in the differential manometer

Rearranging equation (6), and considering the geometry of figure N, we obtain P1 – P2 = H ( γ2 – γ1 )

(7)

Since points 1 and 2 are of the same elevation, z1 – z2 = 0. Substituting equation (7) to equation (5), the final expression for the theoretical discharge will be obtained as

Page

61

(8) The curve of the theoretical discharge Q versus the pressure drop H can be plotted using equation (8). Using an apparatus such as the hydraulic bench, the actual discharge can be determined, and the Qactual versus H can be plotted on the same graph. For any pressure drop H, there correspond two values for the flow rate. The ratio of these values is called the venturi coefficient of discharge C v.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter C v = Q actual / Q theoretical

for any given H

(9)

The actual discharge is different from the theoretical discharge because the effects of friction are not ed for in the Bernoulli equation from which the entire derivation of Theoretical was based. For every C v obtained, there corresponds an upstream Reynolds number which can be calculated using the formula Re = 4 Qactual / πνD (10) Where

ν = kinematic viscosity of the fluid in the venturi meter D = diameter of the pipe

Page

62

Figure 15. Calibration Curve

Figure 16. Cv versus Re plot

With the obtained values, a plot of the discharge coefficient C v versus Reynolds number Re can now be constructed semi-logarithmic coordinate plane.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter The data series 1 of Figure 15 represents the plot of the Q actual versus H; while, data series 2 represents the Theoretical versus H curve. Figure 16 shows the graph of the coefficient of discharge versus the Reynolds number. By inspection, it can be realized from this graph that the coefficient of discharge of a venturi meter approaches unity as the Reynolds number increases. Materials and Apparatus:

Figure 17. The Experimental Set-up (Front view)

Figure 18. The Experimental Set-up (Left side view)

Page

63

Water from the reservoir below enters the tank through a plastic tube inserted on its base section (refer to Figure 18). Before the actual flow measurements were done, the water level in the tank was first allowed to stabilize.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter The height of the water level can be checked and measured using the piezometer tube on the lateral area of the tank (see Figure 19).

Figure 19. Piezometer tube

Figure 20 shows the venturi meter attached to the pipe connecting the two tanks. The tube is made of plastic; thus, the flow of the water can be clearly seen. Venturi meters of a different geometry and even material can also be used. Figure 20. Venturi meter

The piezometer tubes are shown in Figure 21. There are a total of 10 piezometer taps.

Page

64

Figure 21. Piezometer taps

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter

Page

65

Figure 22. Dimensions

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter Procedure: 1. Check all the apparatus and materials to be used in the experiment. Establish the arrangement shown in Figure 17. 2. Only the pressure drop between the inlet and the throat of the venturi meter needs to be calculated. Using a rubber tubing (or any possible type of closed conduit boundary), conne ct the piezometer tubes for the inlet and the throat in such a way to form a differential manometer. Make sure that the piezometer tubes are properly connected. 3. Switch the hydraulic bench on, and then open the butterfly valve to allow the water to through the entire experimental unit. Choose a small discharge first. 4. Wait for the flow to become steady. A steady flow is one in which all conditions at any point in a stream remain constant with respect to time. 5. After the establishment of a steady flow, measure the difference in the piezometric heads, H, in the differential manometer. Calculate the theoretical discharge through the venturi meter using equation (8). The dimensions of the meter are shown in figure N. 6. Measure the actual discharge using the volumetric tank. This can be done by measuring the change in the volume of the water in side the tank per unit time 7. Calculate the coefficient of discharge using equation (9). Then, adjust the butterfly valve to slightly increase the discharge. 8. Repeat steps 4 to 7 until the maximum discharge is reached.

Page

66

9. Plot the Q versus H curve for the venturi meter. Obtain two curves, one for the theoretical discharge and another for the actual discharge, in just one graphing plane (see Figure 15). 10. Calculate the Reynolds number for every coefficient of discharge using equation (10). Plot the coefficient of discharge versus Reynolds number curve.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter Worksheet: Diameter of Pipe: _________ Diameter of Throat:________

Trial

Dimensions of volumetric tank Length:________ Width: ________ Height: _______

Theoretical

Actual

h1

h2

hinitial

hfinal

t

[cm]

[cm]

[cm]

[cm]

[s]

1 2 3 4 5 6 7 8 9 10

Trial

Theoretical H [m]

D2 / D1

Actual

Cv

A2

Q

Δh

Q

[m2 ]

[m3 /s]

[m]

[m3 /s]

Re

1 2 3 4 5 6

Page

67

7 8 9 10

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter Questions: 1. What would happen if piezometers were used (instead of the differential manometer) in measuring the pressure drop between the inlet and the throat of the venturi meter?

2. What would happen to the coefficient of discharge if the venturi meter is positively inclined? negatively inclined? vertical?

3. What are the factors that may reduce the coefficient of discharge of a venturi meter? Is the coefficient of discharge dependent on the geometry of the venturi tube?

4. What is the effect of a smaller ratio of D 2 / D1? of a higher ratio?

6. What can you conclude from the coefficient of discharge versus Reynolds number curve?

Page

68

5. In some cases, precise calibration of the venturi tube gives a value for the coefficient of discharge greater than 1. What could be the reason for such abnormal result?

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Venturi Meter Extension Experiments: 1. Repeat the experiment using a fluid of a different viscosity. Is the coefficient of discharge dependent on the type of fluid used? What can you conclude from the coefficient of discharge versus Reynolds number curve? 2. Repeat the experiment using a fluid with suspended particles. Is there a change in the coefficient of discharge? What is the advantage of using the venturi meter in measuring the flow rate of this type of fluid? 3. Repeat the experiment using a venturi meter having a different inlet and throat diameters. Use water as the confined fluid. What is the effect of varying inlet and throat dimensions on the coefficient of discharge?

Page

69

4. The venturi tube gives a relationship between the pressure drop and the flow rate of the fluid using a convergent and a divergent tube. If a new flow meter is constructed such that the diverging tube comes first before the converging tube, would this be an acceptable flow meter? Repeat the experiment using this new apparatus. Use different fluids.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Flow Nozzle Objectives: 1. To calculate the coefficient of discharge of a flow nozzle 2. To plot the discharge vs. pressure drop (Q vs. H) curve for a flow nozzle 3. To plot the coefficient of discharge vs. Reynolds number (C d vs. Re) curve for different actual discharges Introduction: Another type of discharge-measuring device is the flow nozzle. This instrument consisits of a gradual contraction of its cross section, followed by a short, straight cylindrical portion (see Figure 1). In other words, it looks almost the same as a venturi meter without the diverging discharge cone. It can be installed along the pipeline by simply cutting the pipe, attaching flanges, and inserting the nozzle. As the liquid es through the device, a region of flow separation and reversal exists in the downstream portion; thus, increasing the friction losses in the pipe. The primary aim of this experiment is to calibrate a flow nozzle by calulating its coefficient of discharge. This can be accomplished by plotting the calibration curve (Q vs H) for the nozzle. Furthermore, a graph of the coefficient of discharge versus Reynolds number is to be obtained. It shall be observed at the end of the experiment that the coefficient of discharge of a flow nozzle increases with increasing Reynolds number. Theoretical Background:

Page

70

The Bernoulli equation can be applied to the flow nozzle as was done for the venturi meter in the previous experiment.. The results are identical for the theoretical flow rate.

(1)

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Flow Nozzle Where

A2 D1 D2 H γ1 γ2

= = = = = =

cross-sectional area of the downstream tube (nozzle) diameter of the inlet pipe diameter of the nozzle difference in elevation in the differential manometer unit weight of the fluid in the flow nozzle unit weight of the fluid in the differential manometer

Equation (1) gives the theoretical flow rate through the flow nozzle.

In this case, the elevation differences are considered negligible because the flow nozzle is relatively short. Moreover, the distance between the two static pressure taps (see Figure 1) is also small. In practice, it is desirable an upstream approach length equivalent to about ten pipe diameters to ensure uniform flow at the meter.

Page

71

Figure 1. The Flow Nozzle

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Flow Nozzle

Again, the actual flow rate through the meter is less compared to the theoretical flow rate. This is due to the friction losses that were not ed for in the Berrnoulli equation, where the derivation of equation 1 was based. Thus, we introduce a discharge coefficient for the nozzle defined as C n = Q actual / Q theoretical (2) For every value of the coefficient of discharge, there correponds one pressure drop and an upstream Reynolds number. Re = 4 Qactual / πνD (3) Where, ν = kinematic viscosity of the fluid in the flow nozzle D = diameter of the pipe

Page

72

Using equation (3), the plot of the discharge coefficient versus Reynolds number can now be obtained. At a high Reynolds number, the discharge coefficient is above 0.99. On the other hand, lower Reynolds number gives a lower value for the coefficient of discharge. This is thecase because at relati vely low Reynolds number, the sudden expansion outside the nozzle throat causes greater energy loss; thus, a lower value for C n.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Flow Nozzle Apparatus: The hydraulic bench and the experimental unit 1 are the main apparatuses to be used in this experiment. The venturi meter attached to the unit must be replaced with a flow nozzle. Fifure 2 shows the complete experimental set-up. Figure 3 shows the flow nozzle to be used in this experiment.

Figure 2. The Experimental Set-up

Page

73

Figure 2. The Experimental Set-up

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Flow Nozzle Procedure: 1. Check all the apparatus and materials to be used in the experiment. Establish the arrangement shown in Figure 2, with the flow nozzle (see Figure 3) attached to the test section. 2. Only the pressure drop between the inlet and the nozzle needs to be calculated. Using a rubber tubing (or any possible type of closed conduit boundary), connect the piezometer tubes for the inlet and the nozzle in such a way to form a differential manometer. Make sure that the piezometer tubes are properly connected. 3. Switch the hydraulic bench on, and then open the butterfly valve to allow the water to through the entire experimental unit. Choose a small discharge first. 4. Wait for the flow to become steady. A steady flow is one in which all conditions at any point in a stream remain constant with respect to time. 5. After the establishment of a steady flow, measure the difference in the piezometric heads, H, in the differential manometer. Calculate the theoretical discharge through the venturi meter using equation (1). 6. Measure the actual discharge using the volumetric tank. This can be done by measuring the change in the volume of the water in side the tank per unit time 7. Calculate the coefficient of discharge using equation (2). Then, adjust the butterfly valve to slightly increase the discharge. 8. Repeat steps 4 to 7 until the maximum discharge is attained.

Page

74

9. Plot the Q versus H curve for the venturi meter. Obtain two curves, one fo r the theoretical discharge and another for the actual discharge, in just one graphing plane. 10. Calculate the Reynolds number for every coefficient of discharge using equation (3). Plot the coefficient of discharge versus Reynolds number curve.

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Flow Nozzle Worksheet: Diameter of Pipe, D1: Diameter of Nozzle, D 2:

Trial

Dimensions of volumetric tank Length: Width: Height:

Theoretical

Actual

h1

h2

hinitial

hfinal

t

[cm]

[cm]

[cm]

[cm]

[s]

1 2 3 4 5 6 7 8 9 10

Trial

Theoretical H [m]

D2 / D1

Actual

Cv

A2

Q

Δh

Q

[m2 ]

[m3 /s]

[m]

[m3 /s]

Re

1 2 3 4 5 6

Page

75

7 8 9 10

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Flow Nozzle Questions: 1. What would happen if piezometers were used (instead of the differential manometer) in measuring the pressure drop between the inlet and the nozzle of the flow meter?

2. What would happen to the coefficient of discharge if the venturi meter is positively inclined? negatively inclined? vertical?

3. What are the factors that may reduce the coefficient of discharge of a flow nozzle? Is the coefficient of discharge dependent on the geometry of the device?

4. What is the effect of a smaller ratio of D 2 / D1? of a higher ratio?

Page

76

5. What are the advantages and disadvantages of using flow nozzles over any other dischargemeasuring device?

6. What can you conclude from the coefficient of discharge versus Reynolds number curve?

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating a Flow Nozzle Extension Experiments: 1. Repeat the experiment using a fluid of a different viscosity. Is the coefficient of discharge dependent on the type of fluid used? What can you conclude from the coefficient of discharge versus Reynolds number curve? 2. Repeat the experiment using a fluid with suspended particles . Is there a change in the coefficient of discharge? Is the flow nozzle efficient for all types of fluids?

Page

77

3. Repeat the experiment using a flow nozzle having a different i nlet and nozzle diameters. Use water as the confined fluid. What is the effect of varying inlet and nozzle dimensions on the coefficient of discharge?

Fluid Mechanics for Civil Engineering II

CLOSED CONDUIT FLOW EXPERIMENTS Calibrating an Orifice Meter Objectives: 1. To calculate the coefficient of discharge of an orifice meter 2. To plot the discharge vs. pressure drop (Q vs. H) curve for an orifice meter 3. To plot the coefficient of discharge vs. Reynolds number (C d vs. Re) curve for different actual discharges Introduction: Another type of constriction meter is the so called orifice meter. This instrument is basically a flat circular plate with a hole on its center. (see Figure 1). In other words, it looks almost the same as a ring. It can be installed along a pipeline by simply cutting the pipe, attaching flanges, and inserting the orifice meter. The hole can either be square-edged or sharp-edged. As the fluid stream goes through the plate, it follows a streamline pattern similar to that shown in Figure 1. Downstream of the plate, the flow reaches a point of minimum area called the vena contracta. At this section, the streamlines are uniform and parallel. The main objective of this experiment is to calibrate an orifice meter by calulating its coefficient of discharge. This can be accomplished by plotting the calibration curve (Q vs H) for the orifice meter.. Furthermore, a graph of the coefficient of discharge versus Reynolds number is to be obtained. It shall be observed at the end of the experiment that the coefficient of discharge of an orifice meter increases with increasing Reynolds number. Theoretical Background:

Page

78

The Bernoulli equation can be applied to the orifice meter (Figure 1) as was done for the venturi meter in the previous experiment.. From point 1 to point 2, the theoretical flow rate is found to be

(1)

Fluid Mechanics for Civil Engineering II